Mining cables

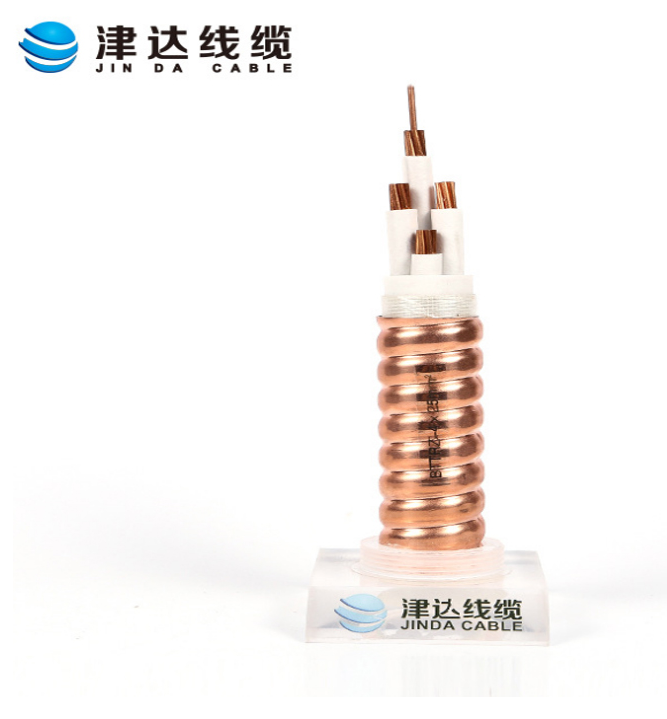

Mining cables are abbreviations for coal mine cables, and mining cables are flame retardant cables, and they should be issued by the National Mining Product Safety Marking Center of Anbiao. U-shaped (M-type) rubber cable for coal mines Mining rubber sleeve flexible cable is suitable for power frequency rated voltage U0/U 8.7/10KV and below mining power plant mobile laying cable.

Keyword:

Category:

Detail

Mining cables are abbreviations for coal mine cables, and mining cables are flame retardant cables, and they should be issued by the National Mining Product Safety Marking Center of Anbiao. U-shaped (M-type) rubber cable for coal mines

Mining rubber sleeve flexible cable is suitable for power frequency rated voltage U0/U 8.7/10KV and below mining power plant mobile laying cable.

In the mine power supply system, the high-voltage power supply line generally uses armored cables, and the failure rate is much less than that of low-voltage power supply. Power supply in the mining area is a weak link in the power supply system, and the working environment is poor, so how to choose the model and section of the cable is related to the safety of power supply operation. The following describes the selection of cables and the selection methods of cable cross-sections.

The choice of cable model has a lot to do with the reliability, safety and economic rationality of power supply. Article 467 of the "Coal Mine Safety Regulations" sets out the following selection requirements for the selection of cables:

1. The horizontal difference of the actual laying location of the cable should be adapted to the specified cable allowable laying level difference.

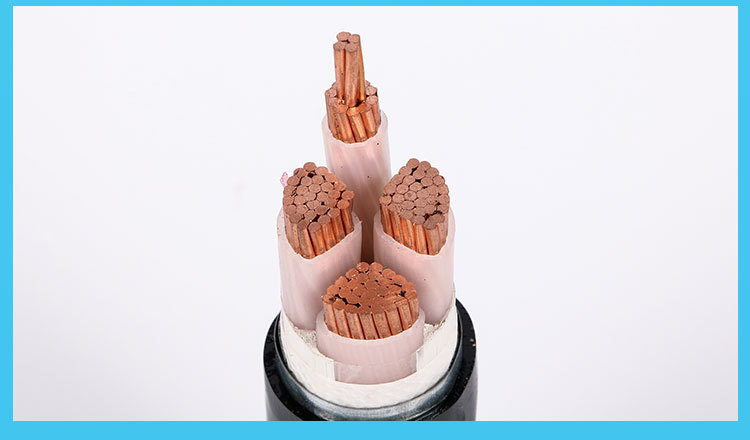

2. The cable should have a conductor of sufficient section for protective grounding.

3. It is strictly forbidden to use aluminum clad cable.

4. Flame retardant cables that have passed the inspection and obtained the safety mark of coal mine products must be selected.

5. The cross-section of the main line core of the cable should meet the requirements of the power supply line load.

In the process of use, the bending radius of the shearer cable is much smaller than the bending radius of the cable specified in the standard, and the cable is frequently subjected to the composite effect of two or more stresses such as excessive bending and stretching for a long time, coupled with the fact that the conductor section of the control wire core is much smaller than the conductor section of the cable main line core, resulting in the fracture of the control core.

1. Increase the flexibility of coal mining machine cables;

2. Increase the relative slip of the control core;

3. Increase the strength of the cable conductor of the coal mine shearer;

4. Change the conductor from the original bundle stranding structure to regular stranding, which can increase its bending performance, and then carry out wire weaving outside the conductor to increase its strength;

5, the control core can be mixed with tinned copper wire and steel wire, which is also a good method.

Inquiry