Mineral insulated cables

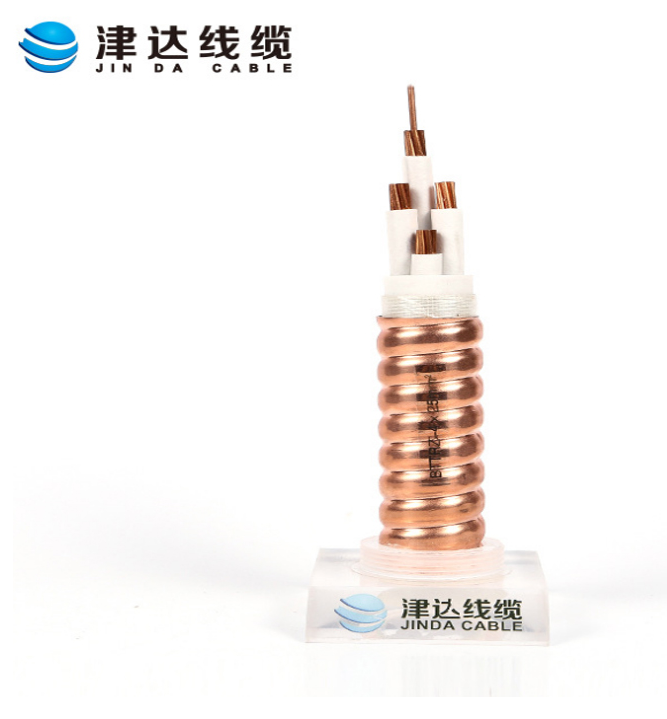

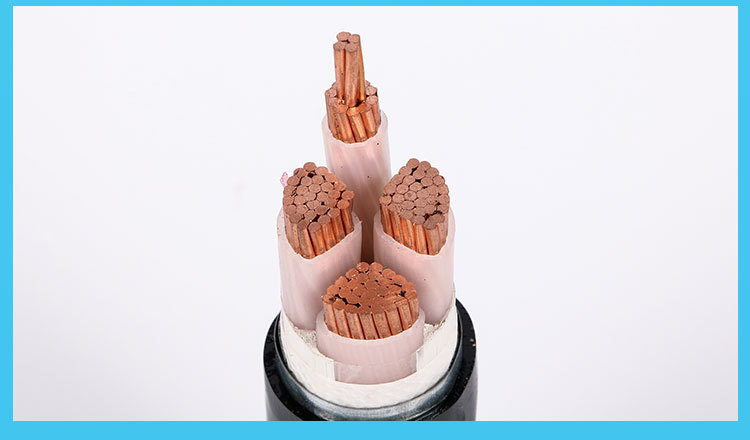

Mineral insulated cable (Mineral insulated cable), a copper sheath wrapped copper conductor core wire, and magnesium oxide powder as an inorganic insulation material to isolate the conductor from the sheathed cable, the outermost layer can be selected as appropriate protective sleeve as needed. Commonly known as MICC or MI cable. There is a similar cable that uses metal instead of copper sheathed to wrap the core and insulation material, called mineral insulated metal sheathed cable (MIMS Cable).

Keyword:

Category:

Detail

Mineral insulated cable (Mineral insulated cable), a copper sheath wrapped copper conductor core wire, and magnesium oxide powder as an inorganic insulation material to isolate the conductor from the sheathed cable, the outermost layer can be selected as appropriate protective sleeve as needed. Commonly known as MICC or MI cable. There is a similar cable that uses metal instead of copper sheathed to wrap the core and insulation material, called mineral insulated metal sheathed cable (MIMS Cable).

Classification and difference of mineral insulated cables:

In addition to the national standard cable (rigid), all other flexible mineral cables are enterprise standards.

Relatively speaking, the national standard cable technology is high, the construction is complex and rigorous, because the metal sheath itself is extremely difficult to bend, the difficulty of installation is the highest, and the need for expensive special accessories, fire performance is also the highest BS6387; The flexible cable installation is similar to ordinary cables, the construction threshold is low, but the fire performance is the same as BS6387, and the application is mainly based on the building fire rating and importance of the selection of matching products.

Rigid mineral cables are limited by the process can not be produced for a long time, the installation uses special accessories, and the bending radius installation can be achieved with special tools to bake guns, bending wheels, etc. (6D). Flexible mineral cable can be continuously produced, different metal sheath structure and has different bending properties, the domestic process mainly has copper pipe (rigid), aluminum tube, horizontal welding corrugated copper pipe, interlocking armored metal sheath, allowing the bending radius to decrease sequentially, the minimum is only 7D (D is the outer diameter of the cable, the bending radius of ordinary cables is about 10D), the design and construction should consider the actual site, cable tray restrictions, and choose the appropriate products. In general, the smaller the allowable bending radius, the less difficult it is to install.

The rigid mineral cable itself is relatively hard, and the impact resistance is also very strong. The flexibility of flexible mineral cable is relatively strong, and the impact resistance depends on the specific structural composition of the corresponding cable. However, all mineral cables except interlocking armored types are difficult to penetrate curved pipe laying, especially for large gauge cables.

Inquiry