Detail

Inquiry

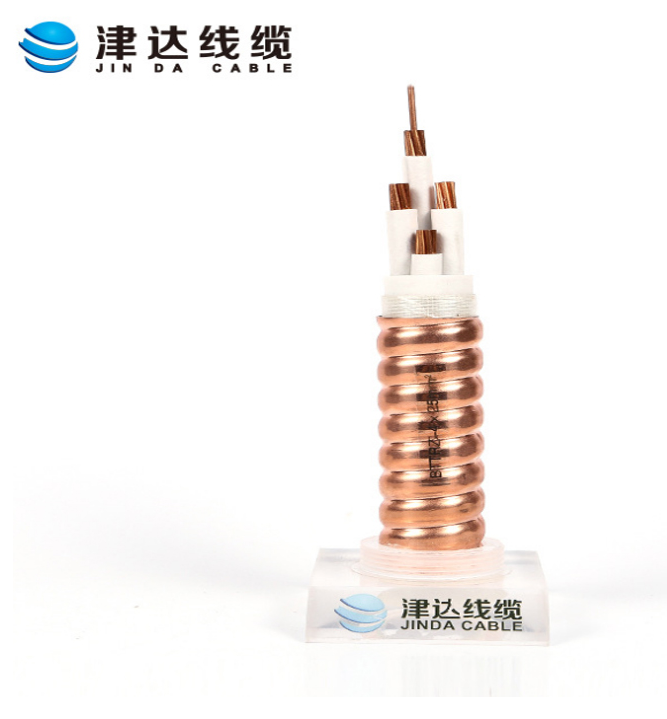

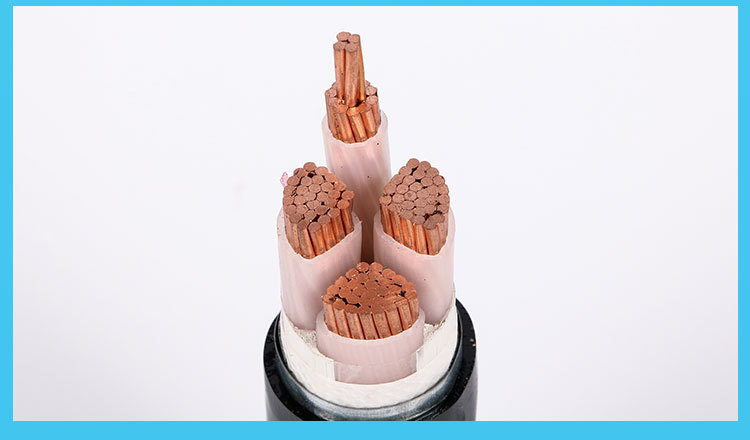

JINDA cable

Mobile: 18602486666 (Liaoning)

Mobile: 18822186666 (Tianjin)

Sales hotline:024-25426666

024-76107777

024-88159999

National sales hotline:400-024-7778

Office address: No. 118, Baogong South Street, Tiexi District, Shenyang

Production base: Yilu Industrial Park, Tieling County Industrial Park