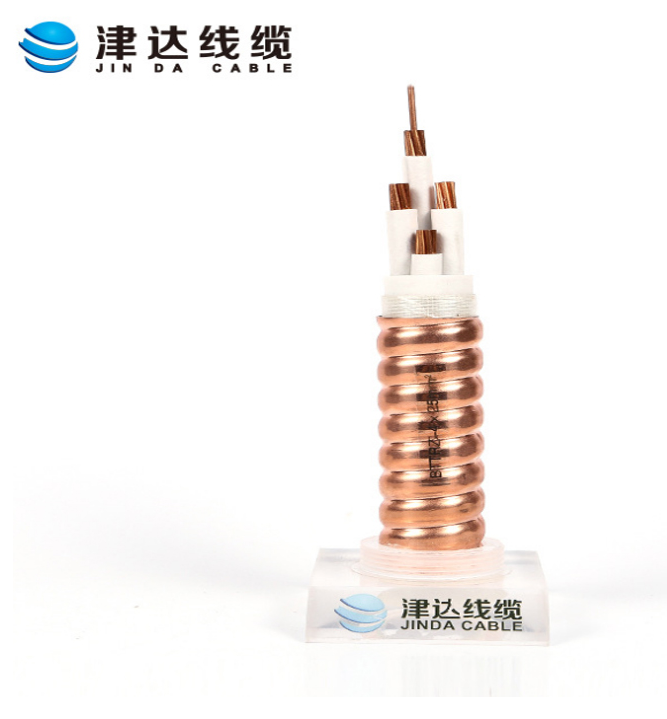

BTTZ cable

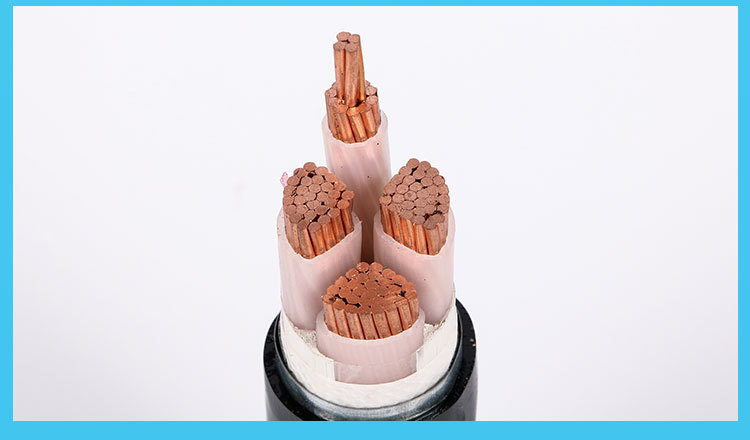

BTTZ cable copper core copper sheath magnesium insulation heavy duty fireproof cable is a smooth copper tube welded from copper conductors, weapon insulation material (magnesium powder) and seamless copper or copper strip vertical wrap. These three materials are high-performance fireproof cables that have been stretched or rolled many times.

Keyword:

Category:

Detail

BTTZ cable copper core copper sheath magnesium insulation heavy duty fireproof cable is a smooth copper tube welded from copper conductors, weapon insulation material (magnesium powder) and seamless copper or copper strip vertical wrap. These three materials are high-performance fireproof cables that have been stretched or rolled many times.

BTTZ cable is resistant to high temperature, fireproof, explosion-proof, non-combustible (250 times can be run for a long time, 1000 limit can also run for a short time for 30min, large current capacity, small outer diameter, high mechanical strength, long service life, generally do not need a separate ground wire.

BTTZ cables are widely used in marine, land, indoor and outdoor, above and below ground. In particular, historical buildings, super high-rise buildings, hotels, shopping malls, hospitals, airports, television stations, communication hub projects, ships, theaters, subways, civil air defense projects, crowded public places, fire-prone dangerous places (such as natural gas plants, chemical plants, oil refineries, etc.) are also suitable for electromagnetic interference prevention, animal bite prevention, waterproofing, nuclear power plants and other special environments.

There are two main methods for producing BTTZ cable series cables in China, one is magnesium oxide ceramic column assembly and multiple drawing annealing. The main processes of this method include inhibition of ceramic columns, sintered ceramic columns, assembly of cables, multiple ignition annealing, water immersion tests, etc. This method is used for the first time in China, and its advantage is to fill the gap that China cannot produce BTTZ cable, with stable performance and high pulling efficiency. Due to the smooth assembly of the copper pipe, the central hull will not cause damage such as cracks during the drawing process, and the pass rate of the pressure test is very high.

The disadvantage is that the process is complex, can not be molded at one time, requires a lot of space to arrange various equipment, and requires a lot of manpower. Due to the limitation of the length of the seamless brass and the elongation coefficient of copper, the cables produced by this method generally cannot reach the long meter segment. In addition, BTTZ cables require the use of special connectors during construction and installation. This special connector is expensive, complex to install, time-consuming, and requires multiple connectors for long-distance wiring, adding a lot of additional costs for the user. Another production method of BTTZ cable is the French cable commonly used in China. According to the main process, we have temporarily named it Copper Belt Zongpu Welding and continuously bundled the high-frequency degradation production line. This method can greatly save space and manpower. It turns out that as long as there are three people, it is possible to produce qualified cables at one time, and the cable length can be produced according to the customer's requirements. It greatly reduces the construction and installation difficulty of customers and effectively reduces the use of special connectors.

Inquiry